By participating in the world’s largest fair, studying fordoctorates and constantly developing our knowledge of the PET industry, we are always enthusiastic about investing in innovative technologies that streamline and improve our business.

Because we are an international company, following trends and contemporary developments in science, we want to meet the requirements and expectations of the most discerning customers from all over the world.

Our investment in state-of-the-art technology sets us apart from the competition, by offering our customers a methodology that will enable them to use our products and patents to save huge amounts of money in their production process.

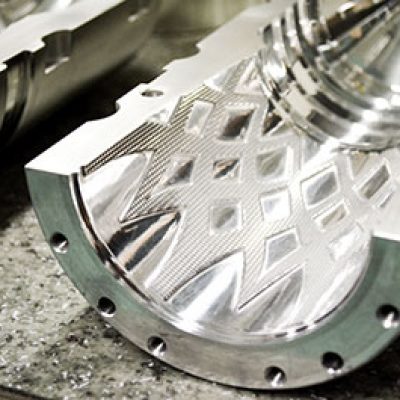

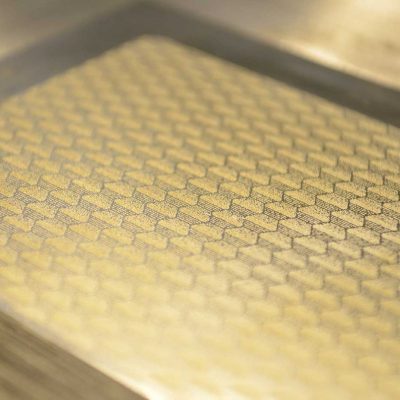

Our patented solutions extend the life of our equipment and reduce production costs, while increasing the functionality of end products.

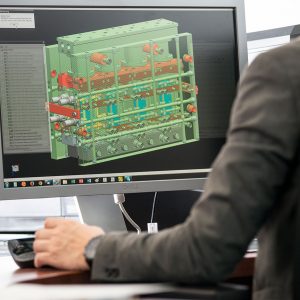

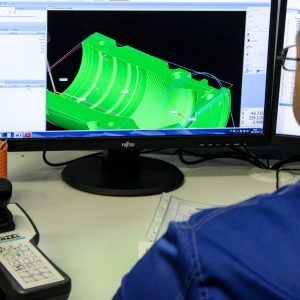

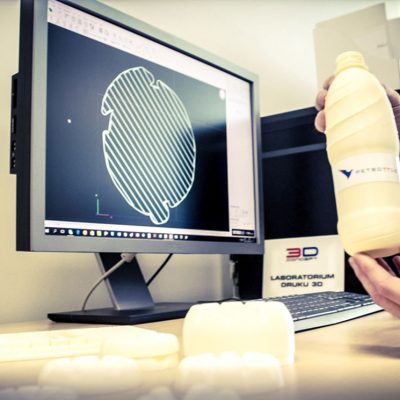

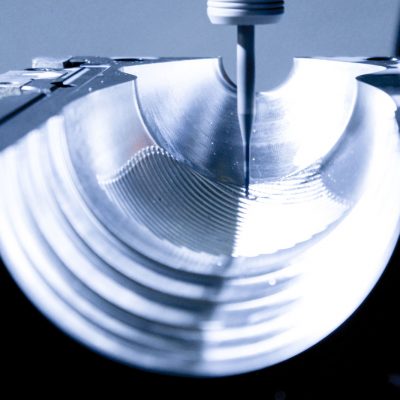

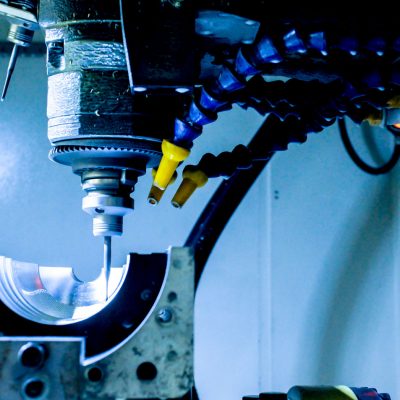

Throughout the entirecreative process, we use state-of-the-art innovative technologies, starting withCAD NX at the design stage, then using FDM-based industrial prototyping (3D printing), 3D scanning (reverse engineering), polishing, anodizing and laser texturing of molds.

We use our own measurement laboratory, machine park and advanced workshop.

We always secure our products professionally for transport, to guarantee responsibility while working with clients, including those in the international arena.

Working with PETBOTTLE, you always receive a guarantee of quality and reliability.Your products will be innovative when compared with the competition, meaning that your PET containers will gain interest and enthusiasmfrom the target consumer.

Copyright © 2014-2017 PETBOTTLE.

Copyright © 2014-2017 PETBOTTLE.