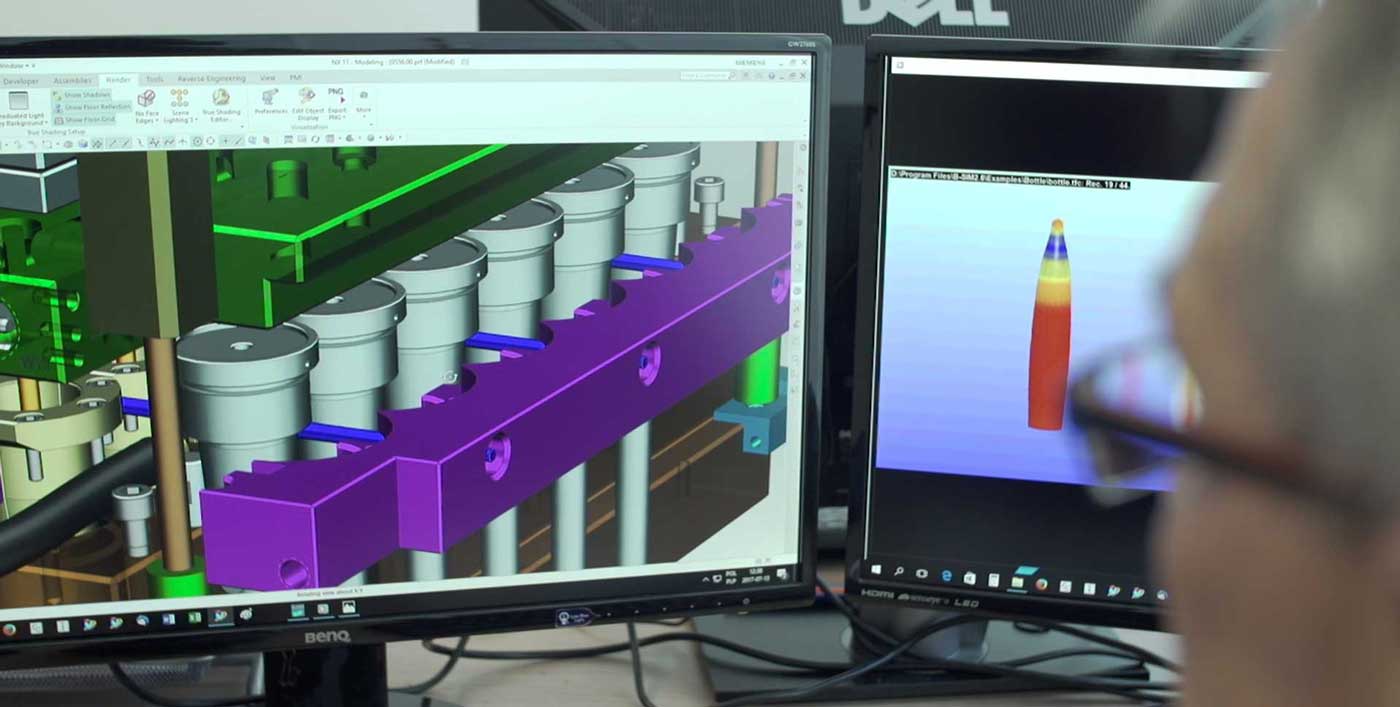

PETBOTTLE is keen to meet everycustomer’s individual needs andprovide a complete service.We offer a wide range of design services and a complete mold set for machines, based on blow molding (ISBM) technology.

We haveour own technical documentation for most machines, so we can make complete mold designs based on these, as well as producing the highest quality spare parts, meeting international standards ISO 9001 and other legal regulations.

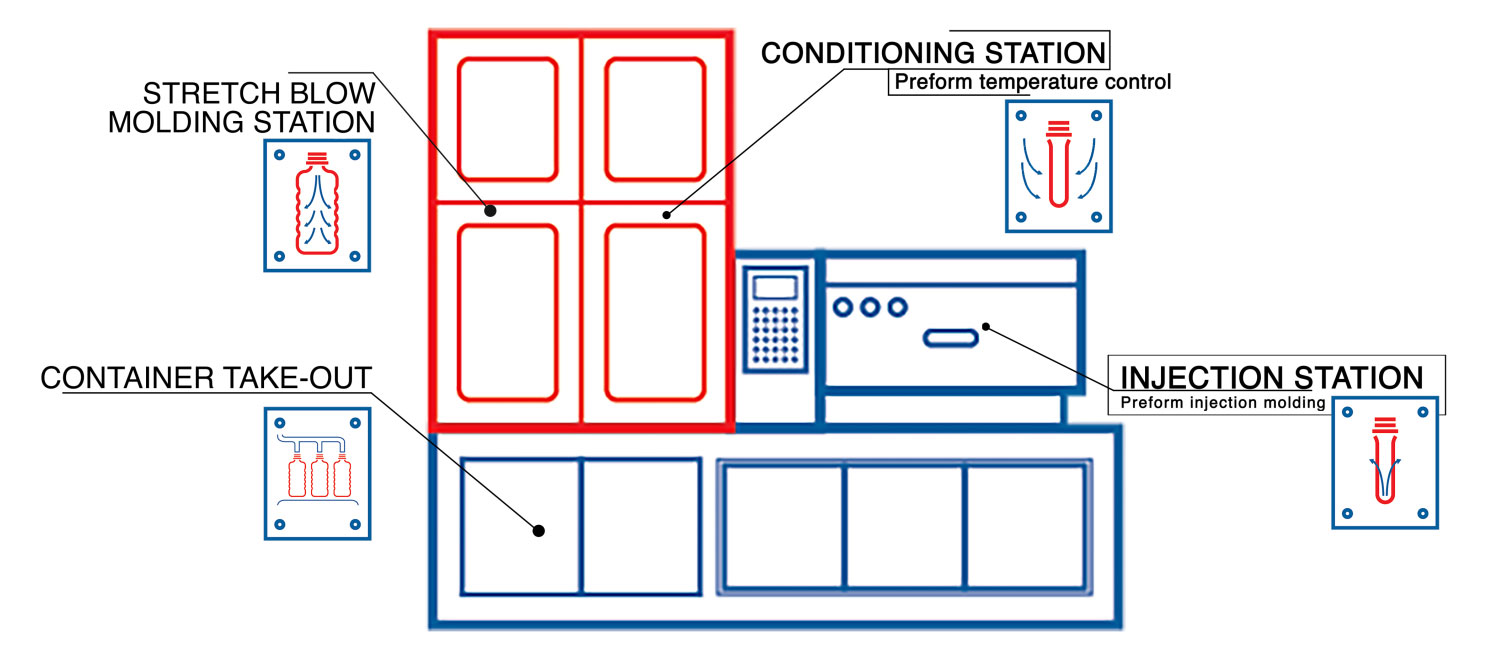

The flexibility of conventional ISBM machines is ideal for non-standard containers.

ISBM is one of the cheapest, fastest but also proven and most effective options for making plastic containers.

With the help of PETBOTTLE, you can achieve your goals and save money on the production process.

Find out more about ISBM machines and their tools, designed and deliveredby Petbottle, and what you receive fromsuch devices.

Copyright © 2014-2017 PETBOTTLE.

Copyright © 2014-2017 PETBOTTLE.