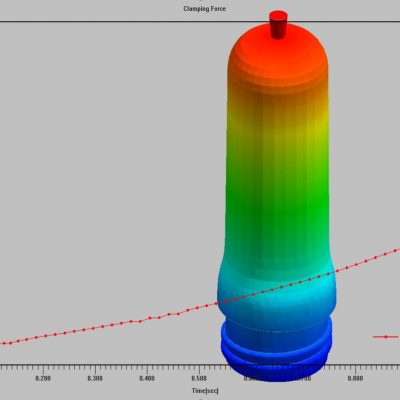

Within a proper process of creating new containers and optimizing existing designs to reduce the cost of production, storage and transportation, it is important to remember that the quality of the finished container and its properties depend on the design of its preliminary mold: the preform.

The ratio of preform dimensions to thefinished bottle is essential to understanding whether the preform is designed appropriately to achieve the planned shape of the container we want to manufacture.

In addition to the PREFORM being properly optimized for injection and blow molding, it must also be properly designed to be operated by other machinery usedfor transport or handling.

Combining all these elements at the design stage is vital for achieving the optimum performance of the process and of the final product.

Copyright © 2014-2017 PETBOTTLE.

Copyright © 2014-2017 PETBOTTLE.